-40%

220V Mini Automatic Water Stained Glass Grinder DIY Desktop Grinding Machine

$ 63.35

- Description

- Size Guide

Description

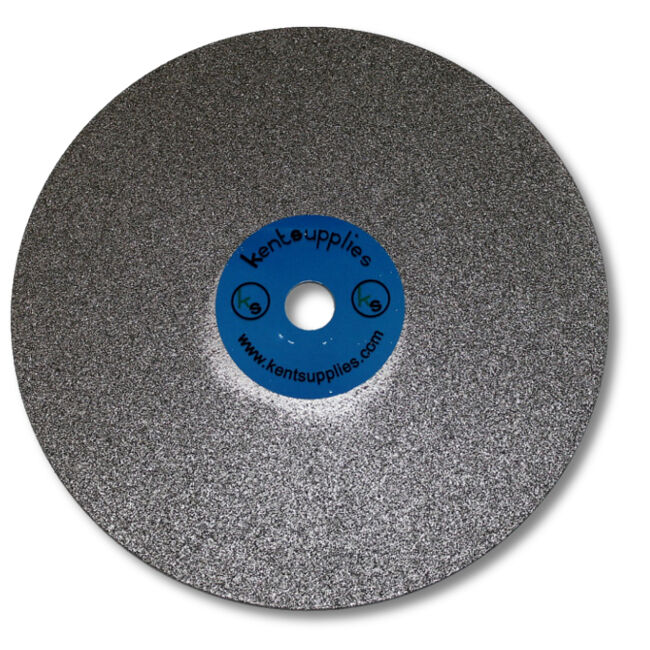

Specification:Color: Blue

Speed: 4200r/min

Voltage: AC 220V, 0.1A

Working table size: 165x165 mm/6.5" x 6.5"

Machine size: 195x195x160 mm/7.7" x 7.7" x 6.3"

Suitable for grinding glass,ceramics and other hard and brittle material.

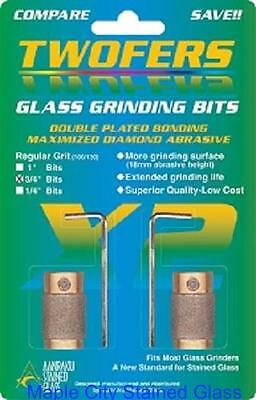

Fit for: MCBL1(1"),MCBL58(5/8")

Package Included:

1 x Glass Grinder with MCBL58

Features:

● Stable and reliable performance.

● Automatic Stained.

● Dents switch design, avoid the leakage.

● Glass, ceramics, such as grinding hard brittle materials.

● Grinding variety of geometric shapes: plane, curve, rounded corners, slope, etc.

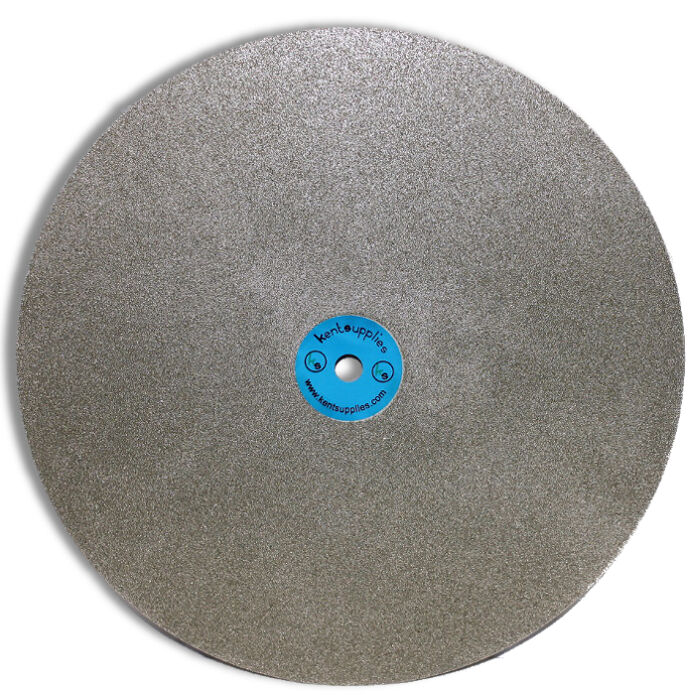

Grinding wheel installation:

1. Before installation of grinding wheel, topped with lubricant, engine shaft grinding wheels need to apply a layer of lubricant inside.

2. The grinding wheel mounted to the engine shaft, the fixed screw position higher than the engine shaft. The position of the grinding

wheel on the axle must be at least 1/8" diamond part above the operating table.

3. Fixed grinding wheel on the shaft with hexagonal wrench clockwisely.

Note: Maintain stability of the grinding wheel installed in the engine shaft of the plane.

Note:

1. Can not grinding without water. Ensure the grinding wheel is wet

2. When using the grinding wheel, with small strength , don't use too much strength.Too much strength will reduce grinding machine and the service life of the grinding wheel.

3. After usement, clean the water reservoir. Remove the reservoir, clean up the rest of the residue after grinding.

4. In order to prolong the service life of grinding machine, cleaning and add lubricant to the engine shaft, 25 hours after each use,

remove all the grinding wheel and the fixed screw.

5. If the grinding wheel not be used for a week or longer,it need to grind down on stage to prevent the direct axis stick on.

This will help you to develop check engine shaft and wheel maintains a habit.

6. Don't grinding metal. If grinding metal, it will damage the grinding wheel and result in can not grinding glass any more.